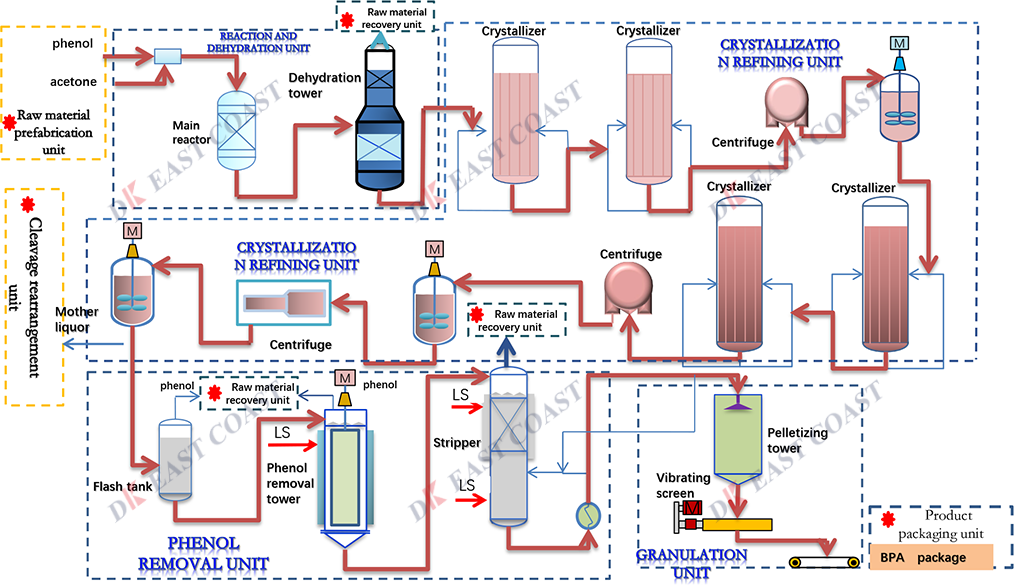

Continuous Production Process: This technology employs a continuous process for producing Bisphenol A using ion exchange resin methods. It allows for easy start-up and shutdown, delivers high and stable product quality, and offers operational flexibility to produce different product grades from the same system.

Cost-Effective Investment: The investment costs are low, as it uses cation exchange resin as a non-corrosive and easily separable catalyst.

Minimal Pollution Generation: Pollution is minimal, generating only a small amount of wastewater with trace phenol and acetone. Solid waste and exhaust gases serve as internal fuel in the process, eliminating the need for additional treatment.