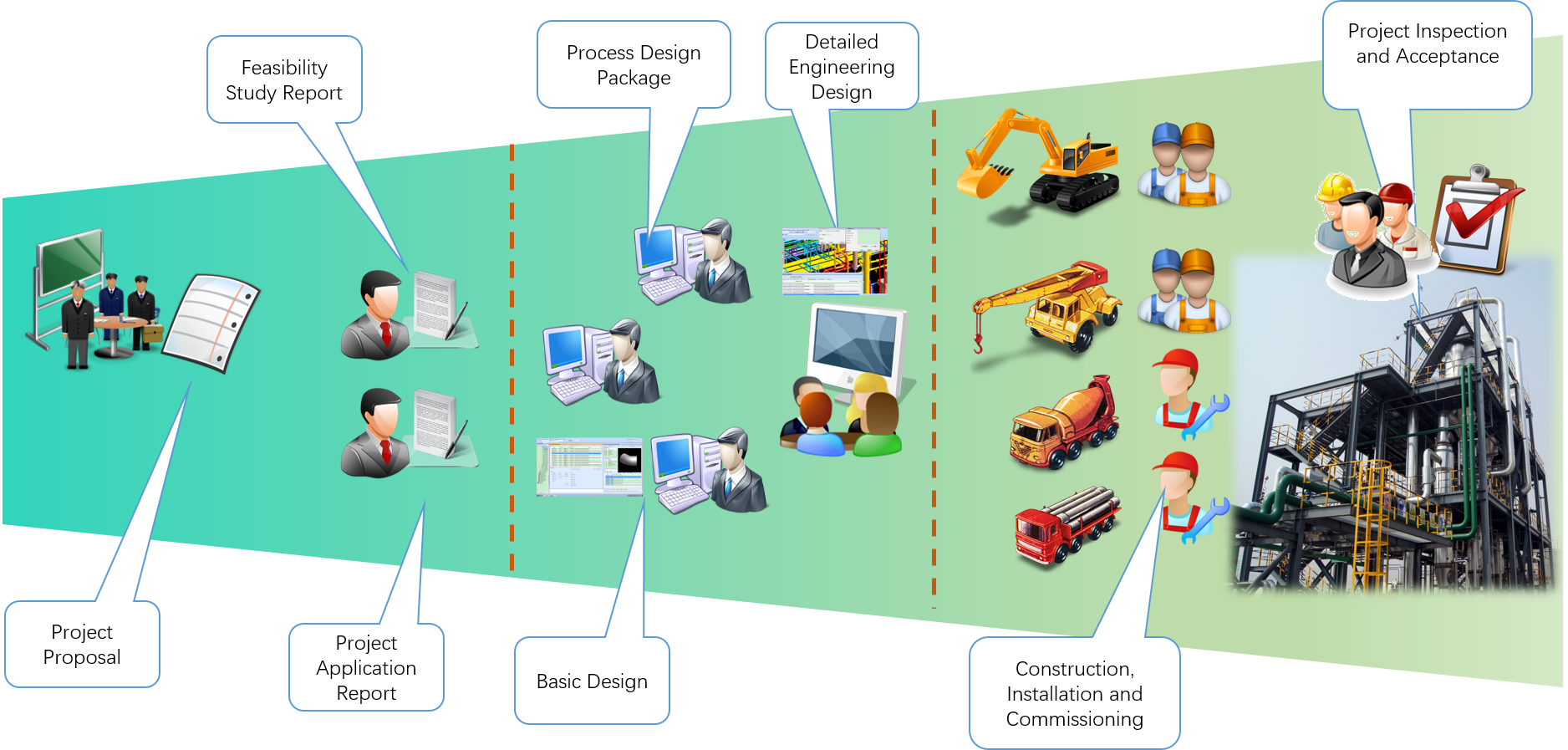

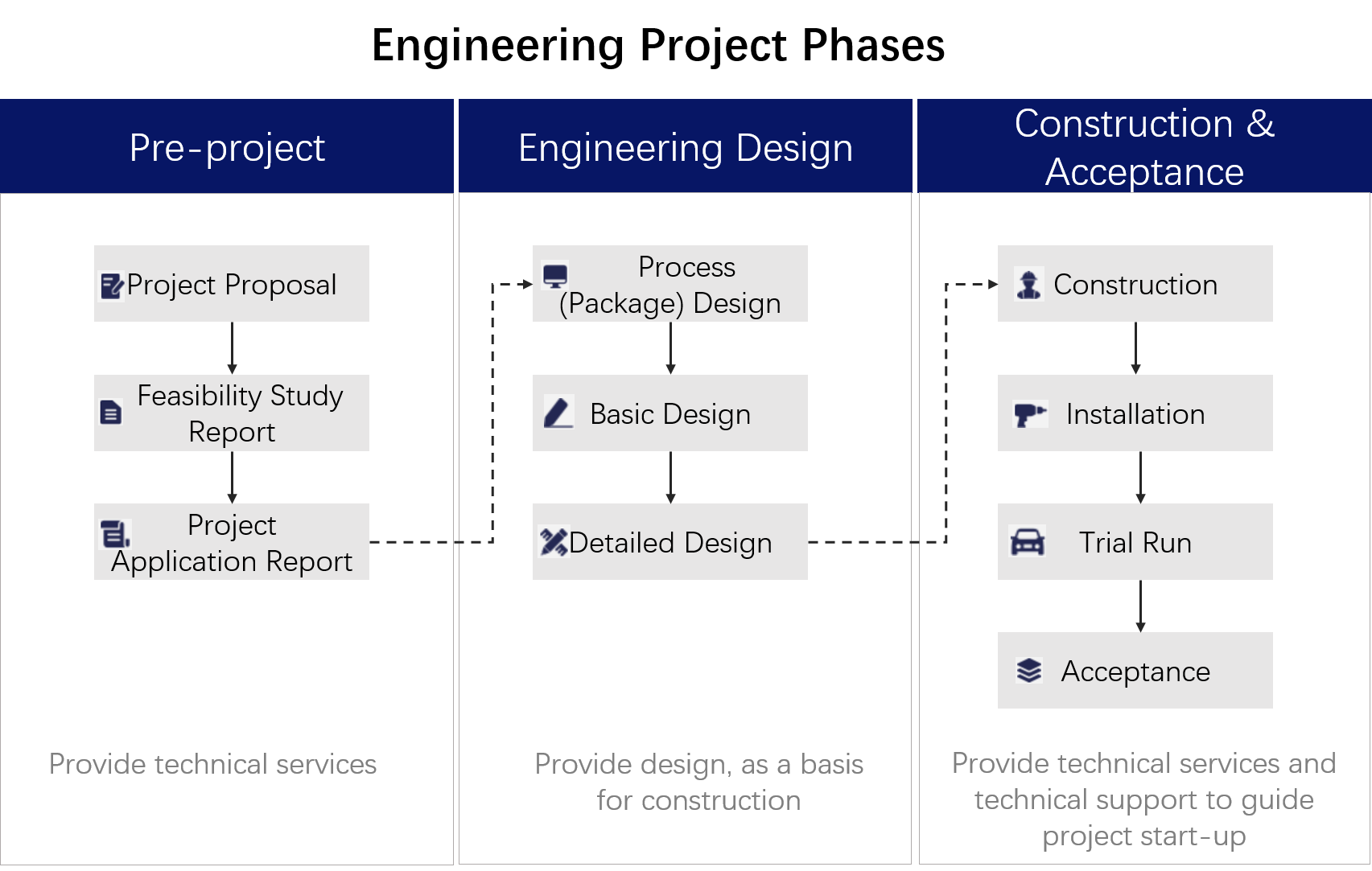

As an excellent international engineering company, DKEC is committed to providing high-level full-process consulting and EPC general contracting services in the petrochemical and pharmaceutical fields. From the customer’s perspective, our technical consulting team can provide customers with professional technical consulting services in all aspects of project implementation, such as analyzing and evaluating the feasibility and return on investment of the project in the project decision-making stage, and recommending the construction scale of the project; The engineering design link adjusts and improves the process route and equipment selection, and the project implementation link recommends measures to control the project cost, etc. The whole-process engineering consulting of the DKEC team can control the entire industrial chain of the engineering project, break the information division of each link, and achieve the effect of helping customers save investment costs, shorten project duration, and avoid project risks.

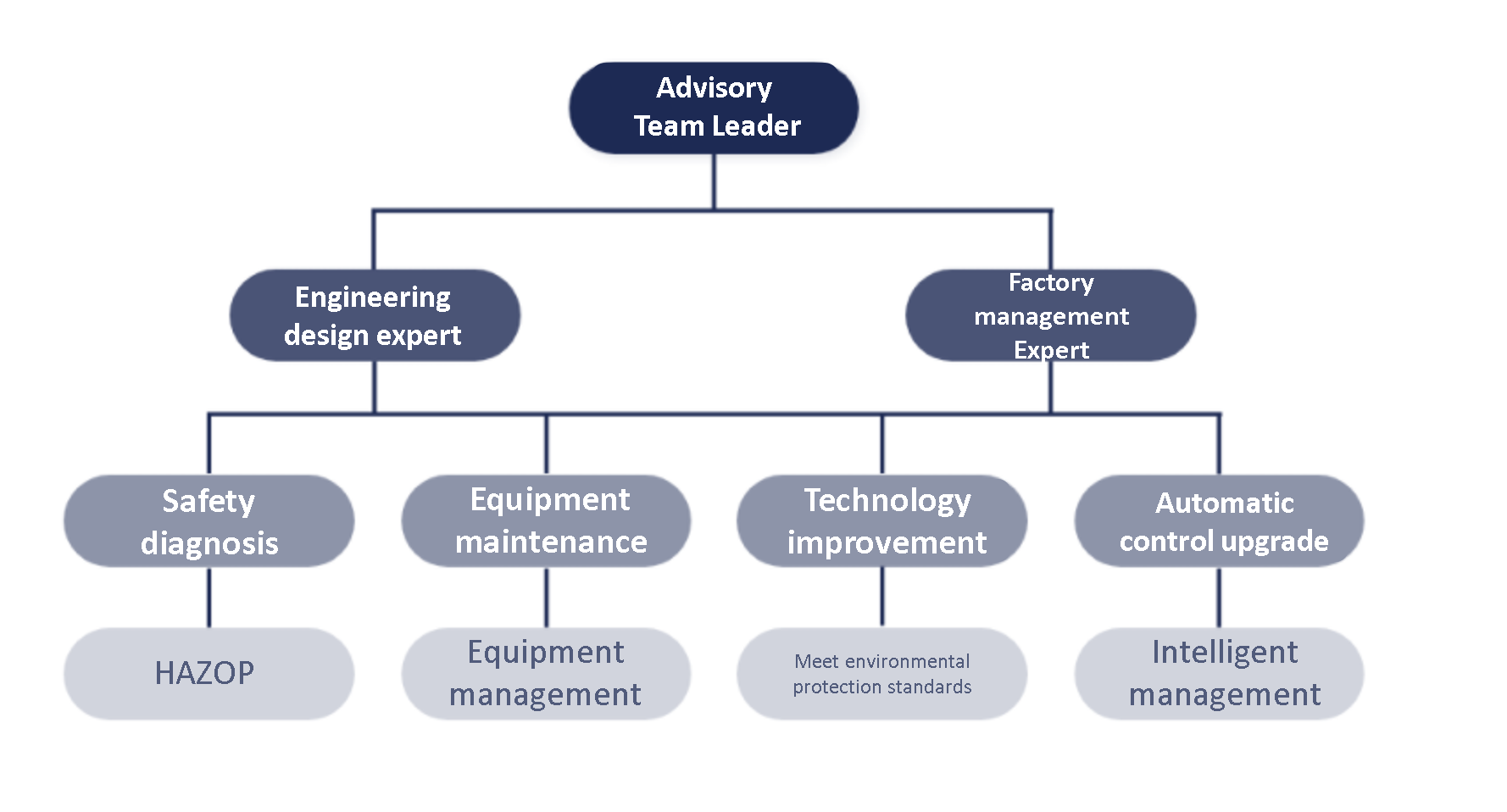

DKEC is equipped with an internationally experienced "Double Ten" consulting team: combining ten years of expertise in chemical industry design and ten years in plant operation and management. Our team of experts provides comprehensive consulting services across multiple domains, including process, technology, equipment, environmental protection, safety, and economics. We deliver tailored diagnostics, design, and retrofit solutions based on client requirements and market demands. Our approach focuses on optimizing processes and workflows specific to each enterprise, while implementing effective treatment for wastewater, exhaust gases, and solid waste. By staying aligned with the green and high-end transformation of the chemical industry, we help enterprises navigate the necessary path for future development and sustainable growth.

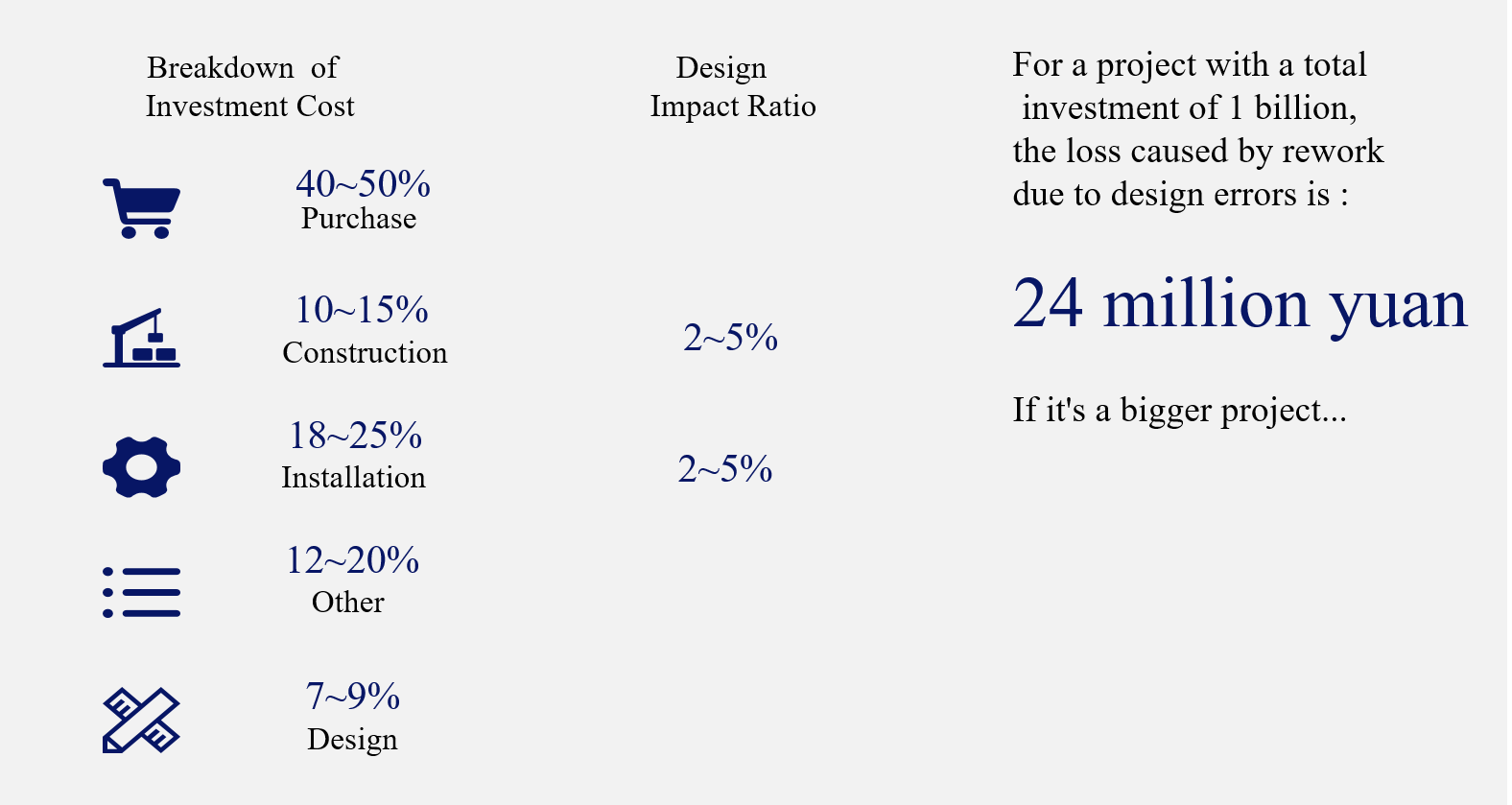

Economic Impact Resulting From Design Errors