- 1.What are HAZOP requirements regulated in China?

- +

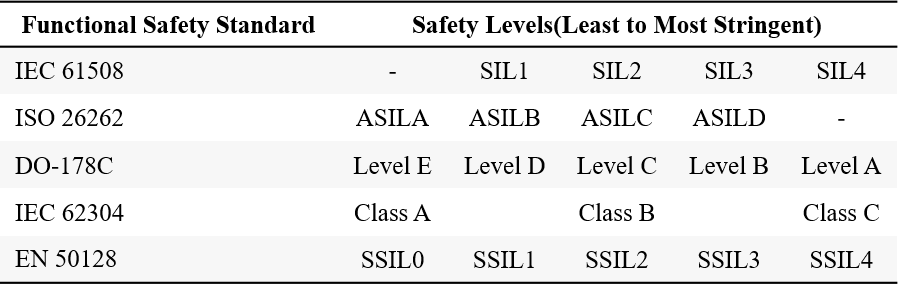

According to the "General Administration of Work Safety of the State Administration of Work Safety [2014] No. 116-Guiding Opinions on Strengthening the Management of Chemical Safety Instrumented Systems": From January 1, 2018, all new chemical plants involving "two important points and one major" will be newly built And hazardous chemical storage facilities should be designed with safety instrumented systems that meet the requirements. For other newly-built chemical installations and hazardous chemical storage facilities safety instrumented systems, from January 1, 2020, relevant functional safety standards and requirements shall be implemented, and safety instrumented systems that meet the requirements shall be designed. Chemical companies and hazardous chemical storage units involving "two key points and one major" in-service production plants or facilities must conduct a comprehensive process hazard analysis (such as hazard and operability analysis HAZOP) and determine the safety instrument function through risk analysis And its risk reduction requirements (ie: safety integrity level SIL rating), and as soon as possible to assess whether the existing safety instrument functions meet the risk reduction requirements (ie: SIL verification).

- 2. How long does a SIL assessments and verification take?

- +

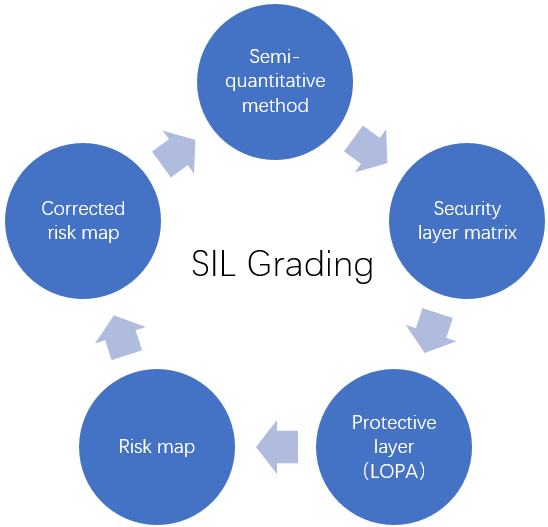

The duration of the SIL rating and calculation depends on the scale of the production unit and the complexity of the process. Typically, it takes 20 to 30 working days. The process involves gathering data on safety, process, equipment, control, and operations, followed by analysis and discussion with relevant experts, and finally preparing the SIL classification and calculation report.

- 3.What information must be gathered in preparation for a SIL assessments and verification?

- +

SIL grading requires data collection:

(1) Safety assessment and environmental assessment report

(2) Summary table of HAZOP analysis recommendations

(3) Process flow and control instructions, operating staff work flow and distribution

SIL verification needs to collect data:

(1) SIL rating report

(2) SIS system safety function requirement specification (SRS)

(3) SIF circuit interlocking logic diagram

(4) SIS system SIL grade specification; SIL grade specification of each purchased instrument.

- 4.Which projects are SIL rating and verification applicable to?

- +

According to relevant laws and regulations from the National State Administration of Work Safety, chemical enterprises and hazardous chemical storage units involved in new or existing production facilities or equipment that fall under the "Two Key Points and One Major" category must implement a Safety Instrumented System (SIS), which requires SIL (Safety Integrity Level) rating and SIL calculation. Additionally, the SIS must undergo lifecycle management, meaning that SIL rating and verification must be re-assessed every three to four years.

[The "Two Key Points and One Major" refers to: key regulated hazardous chemical processes, key regulated hazardous chemicals, and major hazards.]

- 5.What are the benefits of SIL rating and verification for a company?

- +

In terms of safety, SIL rating and SIL verification enhance the company's level of safety production, ensuring safe operations. From a technical and cost perspective, SIL rating and calculation allow for the proper classification of each individual instrument, enabling the company to select an appropriate SIS system. This helps avoid over-purchasing SIS instruments and systems with excessively high SIL levels, ensuring that resources are used efficiently while reducing procurement costs. Especially now, with safety production permits requiring HAZOP analysis, SIL rating, and SIL calculation reports for issuance and renewal, SIL rating and verification have become a mandatory requirement.