The engineering design team at DKEC Group specializes in designing and delivering a diverse range of complex and high-impact projects worldwide. These include fine chemical plants, such as the world’s largest epoxy resin production facility, various fluorochemical plants, environmental projects like brine treatment plants, and a variety of petrochemical and medical facilities. Our team includes chemical, architecture, electrical, instrumentation and structure engineering experts, technology scientists and products portfolio consultants, who have the expertise and commitment to approach every project of any size and any location with a high-performance design strategy.

DKEC basic and detailed engineering design forms the basis for later successful procurement, construction and commissioning work. Our comprehensive front-end engineering and design (FEED) can largely reduce risk and lower total cost of ownership for small and large capital projects.

Most industrial processes rely on digitalization design and automation control, and DKEC has developed digital transformation in executing and delivering projects in all sectors. With DKEC advanced internal IT infrastructure, we conduct engineering design through a data-centric approach in our digital visual platform, enhancing collaboration among different departments and clients’data confidentiality.

Factories now rely on automation control and digital management. We provide Distributed Control Systems or DCS products, solutions, services for continuous or batch chemical process,as well as energy and utility facilities, with multiple controllers for individual components within a plant networked to a central console. This allows feasible batch process management and requires minimal engineering troubleshooting time.

To reduce material costs and project engineering design time, DKEC Group has established a strong 3D piping design team that utilizes the Plant Design Management System (PDMS) and CADWorx,SP3D software for efficient piping design.

This allows vision of actual plant model with exact dimensions and plant space, more convenient for any pipe or equipment modification and plant construction management.

On the original software platform, DKEC has carried out secondary development, building unique design element database, pipe support hanger system and design review procedure.

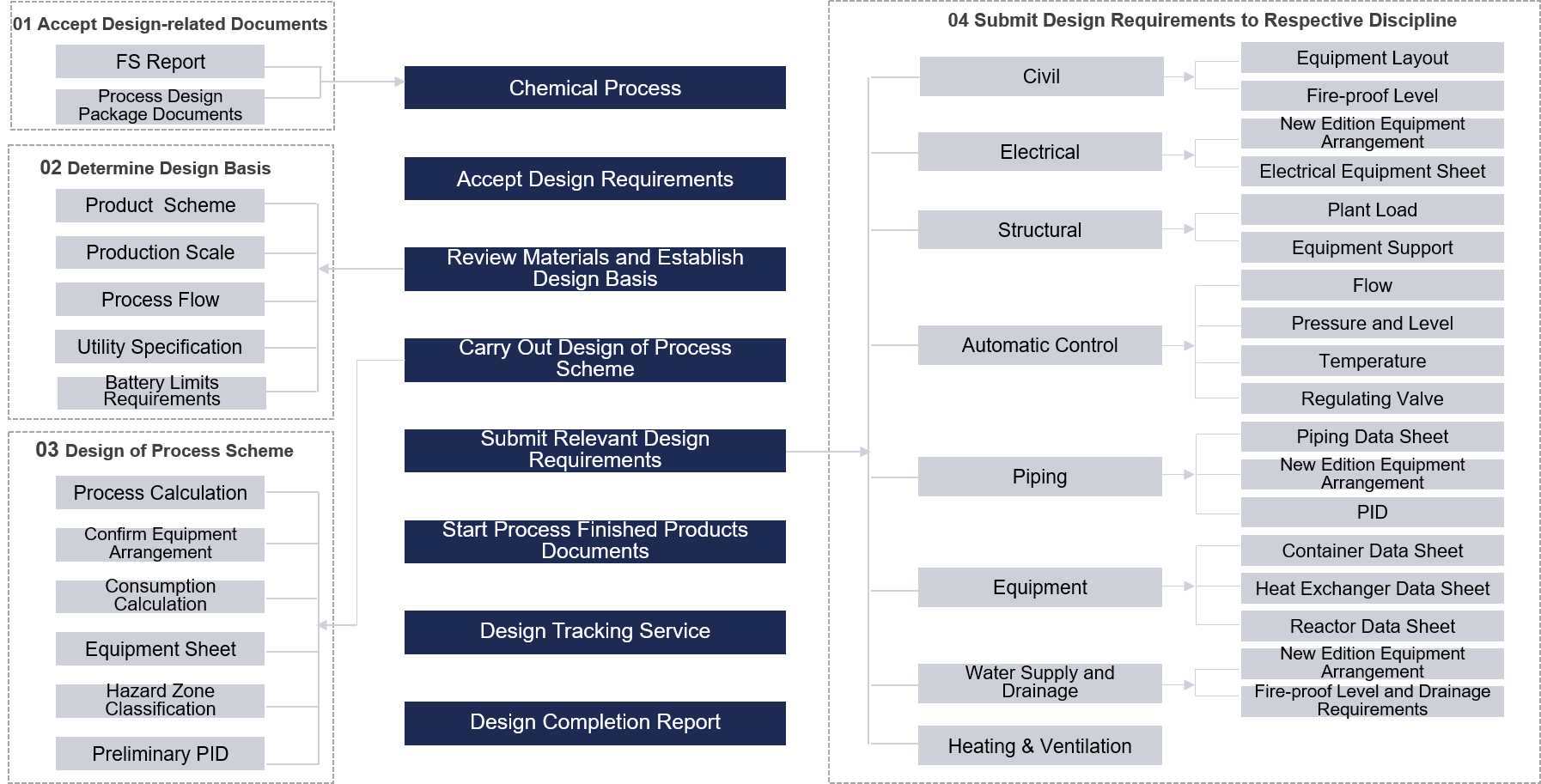

As a leading engineering design company, DKEC Group has developed a comprehensive standard design execution approach for multiple offices collaboration, fast track of input change and consistency control. Our expert team of engineers and designers help transform the Process Design Package(PDP) into outstanding customized engineering design work.

With our abundant experiences in chemical, environmental and medical industries, our engineering professionals not only have thorough understanding and transformation of clients’ process flow scheme, but also have excellent ability of helping clients develop optimal flow scheme. We make practical recommendations for process configurations such as product reactor type and purification method, assisting clients improve and perfect their PDP process.

Process and Instrumentation Diagram (PID) is a typical engineering design result, showing the process flow, equipment, flow piping,valve, sample collection and test instrument etc. As an important reference for equipment and piping layout, PID is used for plant construction and operation guidance.